NEW! The Most Comprehensive and Proven PFAS Solution in North America

Clean Harbors' PFAS destruction surpasses EPA Standards. Partnering with the U.S. EPA and DOD, our study confirms we have the safest and most effective commercial-scale PFAS destruction process in North America.

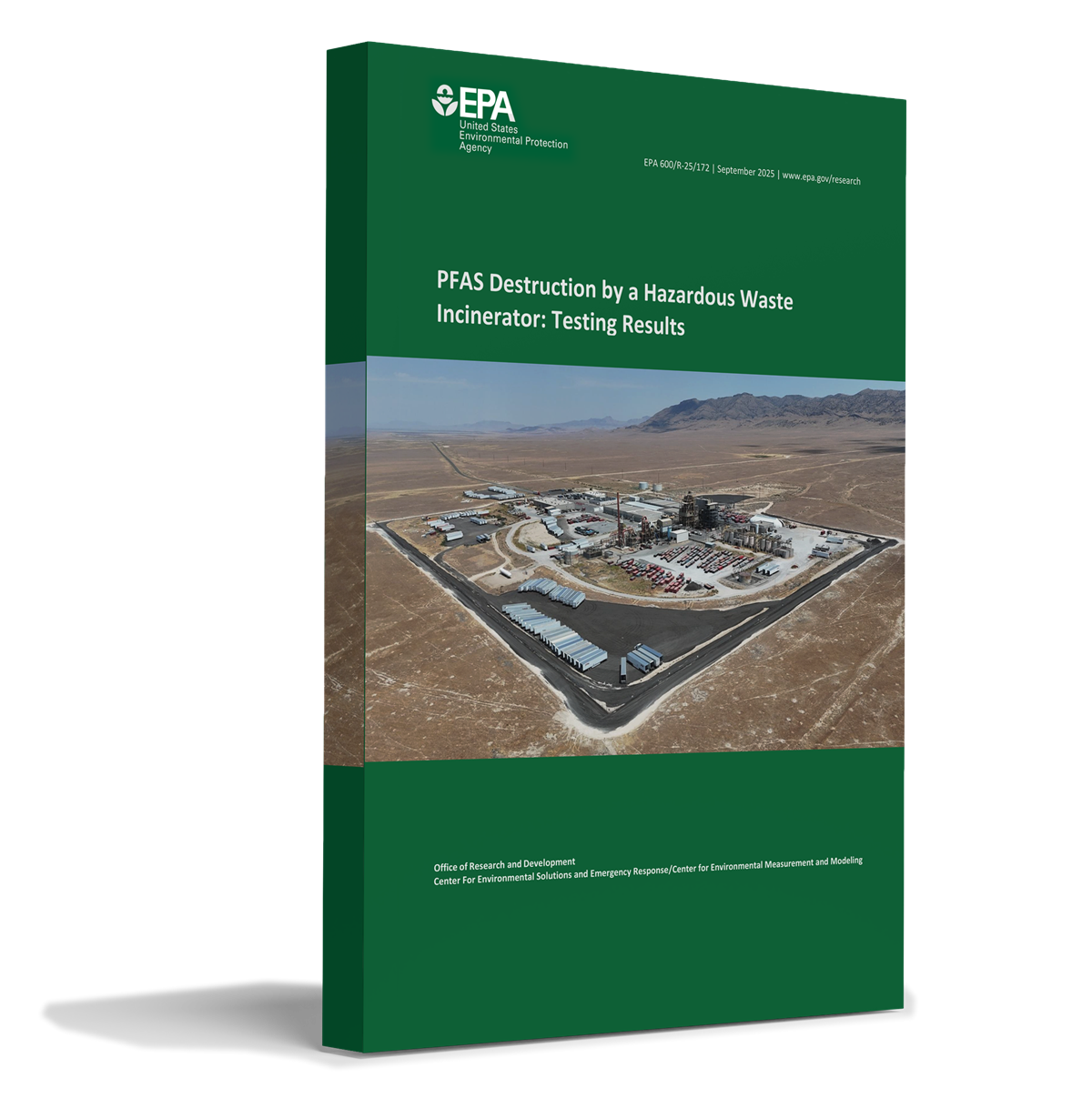

Polyfluoroalkyl substances (PFAS) or "forever chemicals" are linked to harmful health effects in humans and animals. Clean Harbors conducted a PFAS incineration study in conjunction with the EPA and DOD in November of 2024. Results, which were reviewed by third-party experts, were issued in September of 2025 and included: Clean Harbors' RCRA-permitted, high-temperature incineration ensures safe and permanent thermal destruction of PFAS in its various forms. Along with that, destruction can be achieved cost effectively at commercial scale as well as 99.9999% effective in thermal destruction.

Clean Harbors has been solving environmental challenges for over 45 years and we are continuing that commitment with our Total PFAS Solution. Our comprehensive program offers protective, innovative and sustainable solutions that are fully vetted and proven to stand up to the toughest compounds in the world, including PFAS.

The Industry’s Only Single-Source Provider

From cradle to grave, the Clean Harbors Total PFAS Solution is the only program that offers in-house services every step of the way, helping you navigate challenges in today’s complex and evolving regulatory environment.

Proven PFAS Destruction

An independent engineering firm was brought in to test and analyze our PFAS destruction capabilities at our RCRA-permitted incinerators. The results of the test provided conclusive proof that Clean Harbors thermal destruction destroys greater than 99.9999% of PFAS – including PFOA, PFOS, PFHxS, Gen-X PFAS, and AFFF concentrate.

True Comprehensive PFAS Services

PFAS Sampling

Clean Harbors is well versed in sampling and analysis of PFAS compounds. We guide our clients through the process of testing, data analysis, treatment and final deposition of waste. Clean Harbors also provides field sampling to determine PFAS concentrations in water or soil. Our trained and experienced field technicians take representative samples and coordinate their delivery adhering to the strictest chain-of-custody procedures and protocols.

Trained PFAS Sampling Technicians

Clean Harbors can handle the sampling process for you from start to finish. We’ll take care of everything you need including all the required paperwork.

PFAS Analysis

Clean Harbors provides comprehensive analysis of PFAS samples through our network of laboratories, including our newly certified PFAS analysis laboratory in Baltimore, MD.

Analysis Methods

PFAS analysis methods offered through our sampling and analysis program include:

- EPA Method 537.1 (drinking water)

- EPA Method 533 (drinking water)

- EPA Method 1633 (wastewater, soils, solids)

- 537m (wastewater, soils, solids)

Drinking Water Solutions

In the U.S., PFAS is ubiquitous in drinking water. We offer mobile and fixed potable treatment solutions, ready for quick deployment. Our team can help you navigate this challenging environment by making the right decisions for your situation.

Our drinking water services include:

- Certified vessels

- Media – activated carbon and PFAS specific resins

- Mobile systems – from 10 GPM to 750 GPM for fast deployment

- Fixed systems

- Construction support

- Fabrication services

Clean Harbors maintains a fleet of mobile potable use certified media vessels as well as a large stock of media. In addition to our mobile systems we also offer fixed systems, as well as the construction support to build long-term, permanent solutions.

Clean Harbors has extensive experience in providing drinking water treatment systems and can help you navigate this challenging environment by making the right decisions for your situation.

Industrial Water Solutions

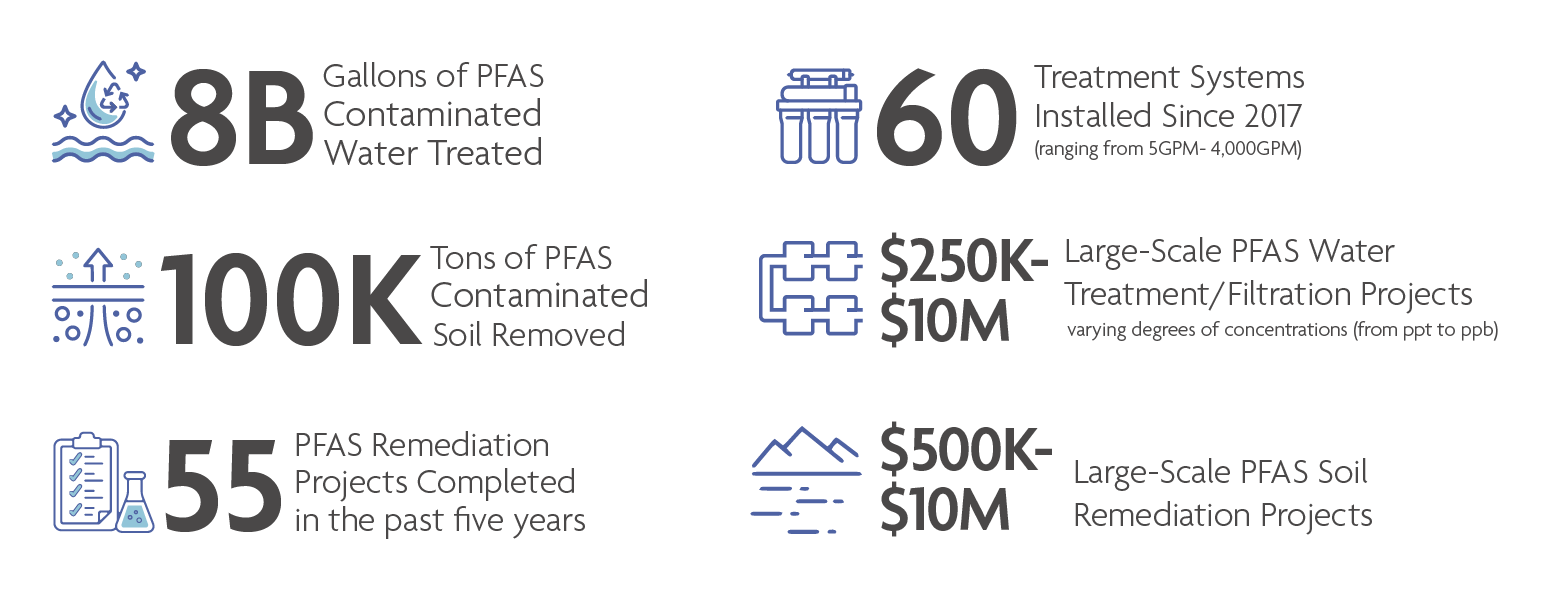

Clean Harbors has been at the forefront of treating industrial and municipal wastewater for clients across the United States since 2017. To date, we have installed and operated over 60 systems at various locations including: AFFF impacted sites, plating facilities, manufacturing facilities, refinery facilities and municipal WWTPs.

Engineering a Comprehensive Plan

Clean Harbors can evaluate the analytical data and project objectives to help develop the most cost-effective treatment plan. Our team of experts works with engineering firms and end-user clients to treat the full lifecycle of the project, including:

- Analytical review of influent water

- Treatment system Installation

- Operation and maintenance

- Spent media management

- Scalable solutions

The Clean Harbors SCID™ approach

Our SCID™ approach allows our customers to meet their strictest discharge criteria including PFAS, metals, TOC, VOCs, SVOCs and TSS. Through our broad selection of adsorptive and IX media, we can identify and implement a treatment train to meet targeted goals including shorter chained PFAS compounds.

- Separate

- Concentrate

- Isolate

- Destroy/Dispose

Soil Remediation - Scalable Remediation Solutions for Any Location

Clean Harbors can handle large-scale, complex site cleanup projects and environmental needs for the public and private sectors. We can remediate any location to meet corporate or regulatory cleanup requirements.

Our remediation services include:

- Sheeting and Shoring

- Dewatering

- Braced Excavations

- Technical Excavation

- On-Site Soil Project Management

National Remediation Team

Clean Harbors has an experienced National Remediation Team to perform complex soil remediation projects. The team can assist in projects requiring the removal of source contamination.

Soil/Media Removal

Excavation and removal of contaminated soil/media is utilized for localized contamination and point source removal. The scale of removal can range from 30 cubic yards of contaminated soil to 20,000 cubic yards of contaminated soil at a large manufacturing facility.

The Clean Harbors Difference

As a single-source provider, one call anywhere in the continental U.S. and Canada will give you access to a Clean Harbors team that handles all aspects of the excavation including panning/sequencing, obtaining permits, waste management, and health and safety.

AFFF Management

Clean Harbors specializes in the safe removal and destruction of Aqueous Film Forming Foam (AFFF), a firefighting foam containing toxic PFAS chemicals. The disposal of AFFF is strictly governed by a variety of regulations at the federal, state, and local levels.

The presence of PFAS may classify AFFF as hazardous waste, necessitating specific disposal techniques. Clean Harbors is equipped to handle all of your hazardous and non-hazardous waste types including AFFF and PFAS, keeping you safe and compliant.

Sustainable Alternatives

As the industry moves from fluorinated AFFF to less toxic alternatives we can help you with the transition. Clean Harbors offers a suite of sustainable solutions including line cleaning, system dismantlement, line rinsing, foam replacement, transportation and disposal of AFFF, AFFF rinsate, and contaminated debris.

If you have AFFF, reach out to Clean Harbors immediately. Our expertise in managing AFFF and PFAS ensures the disposal of your waste is handled in accordance with all regulatory requirements.

Transportation - Comprehensive Waste Transportation Solutions

Clean Harbors provides the widest range of transportation options for waste materials. With our nimble logistics, we can manage and coordinate shipments throughout North America. Our turnkey approach to waste transportation creates a wide variety of options and liability protection. With over 20,000 company-owned vehicles, Clean Harbors is one of the top 15 private carriers in North America.

Clean Harbors Can Handle all of Your Waste Transportation Needs

Clean Harbors provides efficient and safe waste transportation of solid hazardous and non-hazardous waste. Organizing multiple vendors is costly, time-consuming and it can leave gaps in your hazardous waste program that increases your risk or leaves you open to problems with compliance.

Our Extensive Transportation Inventory

- Van trailers

- Lugger boxes

- Tankers

- Intermodal

- Vacuum trucks

- Vacuum boxes

- Frac tanks

- Gondola cars

- Bulk-liquid rail-cars

- Over-the-road-trucks

- Roll-offs

- Box trucks

- Tank trailers

- Dewatering boxes

- Vacuum trailers

- Isotainers

- Flatcars

- Intermodal rail

Disposal - Permitted Hazardous Waste Incinerators

High temperature, hazardous waste combustion that is MACT EEE compliant is the premier destruction technology. Our permitted, hazardous waste, incinerators operate at temperatures above 1000 C which is required for destruction of the PFAS molecule. These facilities have 7 steps in the destruction process to ensure the best available destruction technology.

We have the largest hazardous waste incineration capacity in North America with over 600,000 tons per year. Our incineration infrastructure has proven its effectiveness by being an integral part in the success of the Montreal Protocol by destroying CFC’s. We have destroyed tons of CFC’s and HFC’s, in compliance with the Protocol, TEAP Guidelines, and Title 81 of the Clean Air Act.

Our high-temperature permitted incinerators crucial in destroying these harmful compounds, and stopping the spread of the hole in our ozone layer. This network of destruction facilities is ready to take on our next great environmental challenge by destroying this similar class of recalcitrant compounds, PFAS. Each is located in:

- Aragonite, UT

- Deer Park, TX

- El Dorado, AR

- Sarnia, ON

- Kimball, NE

No one is better positioned to help you minimize your PFAS liabilities than Clean Harbors, through our unmatched network of hazardous waste facilities. Our suite of services includes high-temperature permitted, high-temperature, hazardous waste incinerators; regulated TSDFs; and closed loop permitted landfills. Your liability ends as soon as we pick up your waste. Depending upon your need, Clean Harbors’ Total PFAS Solution has a sustainable answer.

Closed Loop Permitted Landfills

To minimize your liability, these closed loop landfills manage their leachate on premises, or at a permitted hazardous waste, high-temperature incinerator. No need to worry about involving a third party to manage your PFAS liability, Clean Harbors is your single-source solution.

Your PFAS liability never leaves the custody of Clean Harbors for the lifecycle of the waste. For certain levels of PFAS, our closed loop landfills offer direct placement in double-lined cells with leachate collection, and solidification services for liquid streams. For higher PFAS concentrations, we offer high-temperature, incineration. These facilities are located in:

- Lone Mountain, OK

- Grassy Mountain, UT

- Lambton, ON

- Sawyer, ND

- Buttonwillow, CA

PFAS Study Results

Proof that Clean Harbors thermal destruction destroys >99.9999% of PFAS introduced

Clean Harbors recently conducted a comprehensive PFAS performance test at the Aragonite, UT, facility. The following are the results of this study. PFAS Thermal Destruction PFAS compounds contain carbon-fluorine chemical bonds similar to ozone depleting substances (ODS). Clean Harbors has effectively destroyed ODS chemicals for decades under the Montreal Protocol.

PFAS Treatment

Growing concern over the ubiquity of per- and poly-fluorinated alkyl substances (PFAS) in environmental media and growing evidence of adverse human health and ecological effects from this family of chemicals is driving the need to identify effective PFAS remediation and destruction technologies. Due to the strength of multiple carbon-fluorine

(C-F) chemical bonds in these compounds, many PFAS are difficult to degrade, both in-situ by either normal environmental degradation pathways or in-situ treatment technologies, or ex-situ by various treatment technologies. This makes high-temperature thermal destruction a prime candidate for eliminating “environmentally terminal” (not easily degraded further in the environment) PFAS chemicals.

PFAS Test Protocol

These test conditions were run.

1. Normal waste feed

2. Normal waste feed spiked with 4 PFAS surrogates.

3. Normal waste feed spiked with AFFF

EPA OTM-45 method was used for stack sampling. The PFAS analytical method was LC/MS/MS with DOD Isotope Dilution –capable of detecting 49 analytes. EPA Method 26-A was used to measure hydrogen fluoride.

Hazardous Waste Combustors

Hazardous Waste Combustors (HWC) effectively destroys RCRA and CERCLA wastes and complex organic waste streams, including the Halogen Series Compounds e.g. PCBs, CFCs, Brominated Compounds.

HWC Technology Elements include:

• Primary combustion chamber (1100 to 2300 F)

• Secondary combustion chamber (1400 to 2000 F)

• Spray dryer

• Acid gas scrubbing technology to neutralize HCL, H2SO4 and HF acid vapors

• Particulate filtration (primary two-stage baghouse configuration)

• Deer Park and El Dorado NOx removal

• Polishing carbon filtration to remove Dioxins and Mercury

• Residual solids from incineration are disposed at a Clean Harbors Landfill

PFAS Test Results

• Destruction Removal Efficiency (DRE) was >99.9999%

• Stack gas emissions modeled using EPA AER MOD and are 5-8 orders of magnitude below any state or federal ambient air quality guideline in existence.

• Hydrogen fluoride created during combustion was captured and removed with the acid gas scrubbing equipment.

• Industrial grade wastewater treatment