Mud Cleaning and Solids Separation Solutions to Support Trenchless Drilling Projects

As local, county, and state governments continue to implement stringent environmental regulations on drilling waste disposal, drilling and utility companies face increasing challenges and costs for disposing of drilling fluid and waste. Clean Harbors has established itself as the leading provider of trenchless services and solids control solutions in the trenchless industry. Reach out today to consult with a sales specialist for your next trenchless project and discover our advanced trenchless technology options.

We know it can be challenging to find competent environmental and geotechnical drilling contractors who have the resources available and are capable of carrying out the job. Clean Harbors can solve your problem. Submit the form below for exclusive access to our Solids Control Solutions fact sheet.

Whether you work with one of our lines of business or several, such as Line Locating or Hydrovac, we will work collaboratively to ensure the most cost-effective approach is delivered.

Clean Harbors Trenchless Division – Mud Cleaning/Solids Separation:

Clean Harbors Separation Plant

- First cut capacity – 300 GPM

- Slurry processing capacity – 100 GPM

- Solids processing capacity – 5 TPH

- Footprint – 30' x 25'

- Single DFTS Shaker Tank – 420 gal

- Poly Injection Tank

- Single H&H 5500 centrifuge on conventional stand

- 2,500-gal fluid storage tank

- Compatible for a Vermeer D8x12 or similar

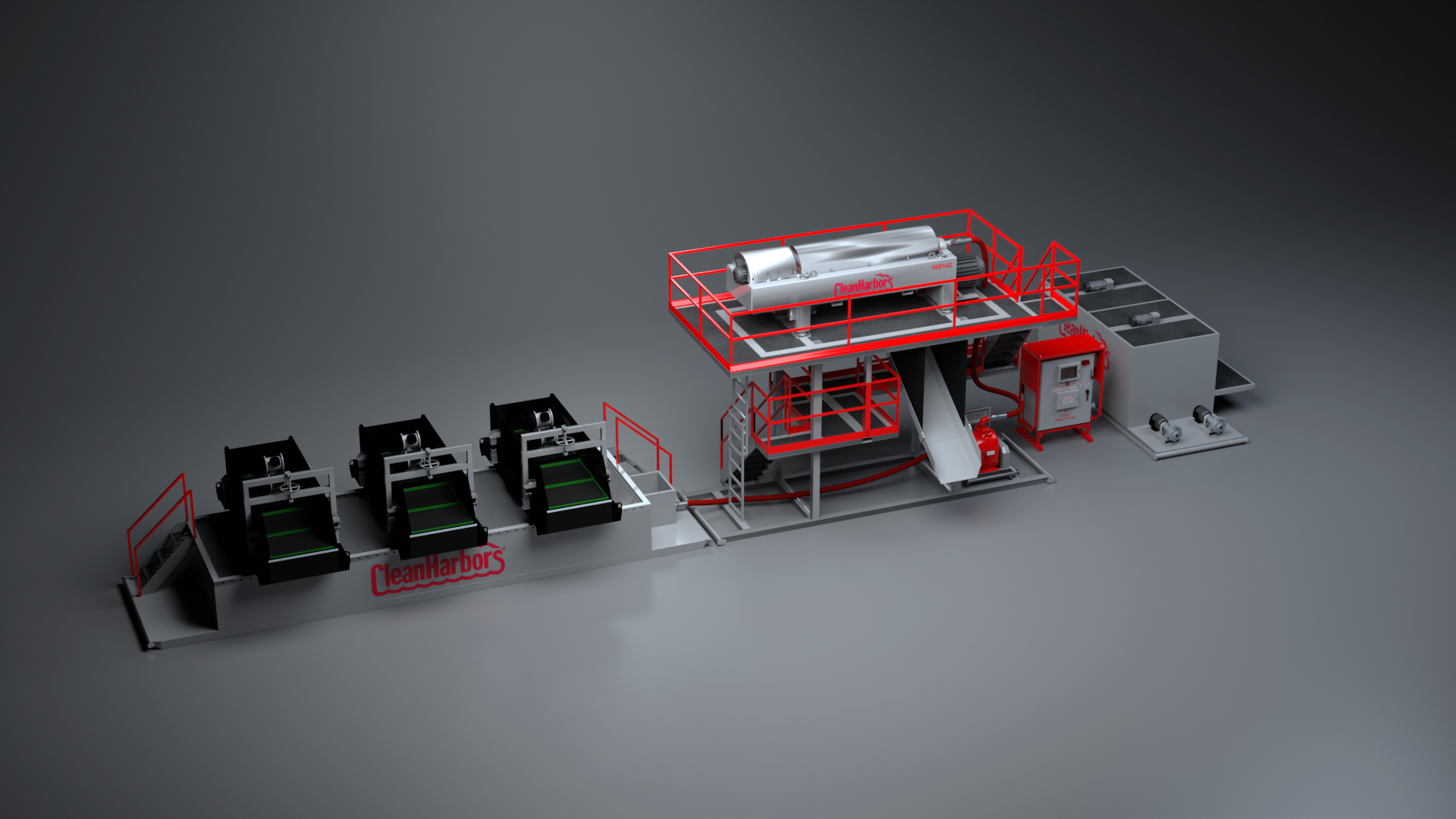

High Output Separation Plant

- First cut capacity – 1,200 GPM

- Slurry processing capacity – 200 GPM

- Solids processing capacity – 10 TPH

- Footprint – 23' x 54'

- MST Tank – 1,260gal capacity

- 5,500-gal fluid storage tank

- Poly Injection Tank

- Dual H&H 5500 centrifuges

- 6,760 gallon fluid capacity

- Compatible with a Vermeer D100 x 140 or similar

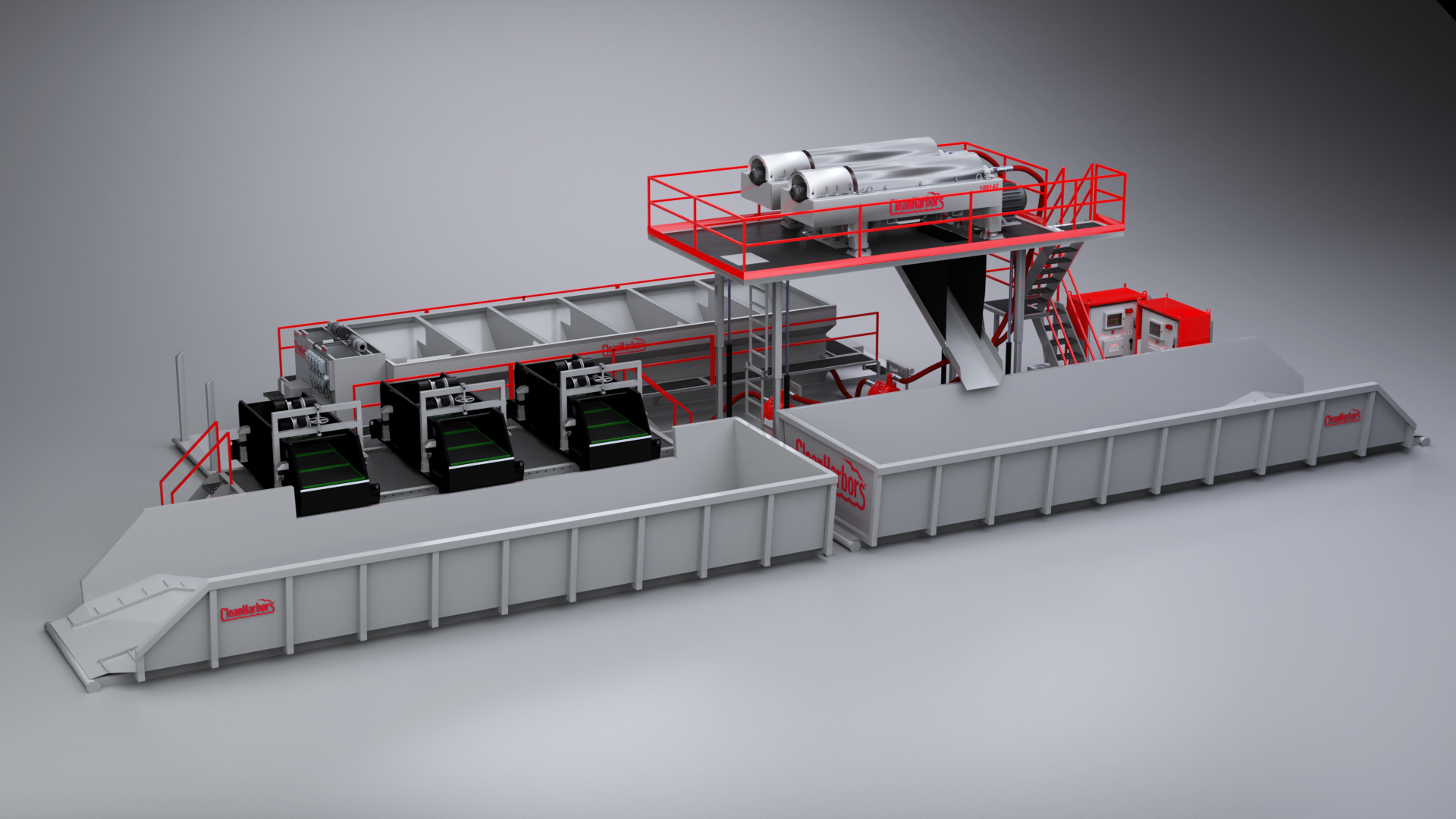

Clean Water Circulation System

- First cut capacity – Up to 3,000 GPM

- Slurry processing capacity – Up to 1,000 GPM

- Solids processing capacity – Up to 24 TPH

- Footprint – Pending Project Plans and site walk-throughs

- MST Tank – 1,260-gal

- Premix Tank – 16,800 gal

- Auger Tank – 6,300 gal

- Big Bowl centrifuge on hydraulic stand

- Build to suit

- Total system fluid capacity – Up to 24,360 gal

- Compatible with any Micro-Tunneling or HDD Maxi-Rig Projects

Not sure where to start? Submit the form below and we'll work through next steps with you.

You can also call (844) 737-2669 or email us at HDDRentals@cleanharbors.com.

Services Include:

Micro-Tunneling Solids Control

Horizontal Directional Drilling Mud Reclaimers

Geo-Thermal Drilling Solids Control